Working principle of hybrid solar air conditioning

The hybrid solar air conditioning system is not a single fixed technical route, but a product of the integration of multiple technologies, aiming to overcome the intermittent or single energy efficiency limitations of pure solar systems. Its core principle is to intelligently integrate different energy inputs and cooling modes to ensure efficient and stable cooling under various working conditions.

Solar photovoltaic and thermal energy combined drive (PV-Thermal Hybrid)

This hybrid mode combines solar photovoltaic (PV) power generation with solar thermal utilization, each driving different cooling mechanisms or assisting each other.

Working principle:

Photovoltaic part: Solar photovoltaic panels convert solar radiation into electrical energy. This electrical energy can directly drive traditional mechanical compression air conditioning units (including compressors, fans, etc.) to provide cooling.

Thermal energy part: Solar collectors convert solar radiation into thermal energy, and the generated hot water or hot air can drive absorption or adsorption chillers, or be used for dehumidifiers in regenerative dehumidification air conditioning systems.

Cooperative work: When there is sufficient sunshine, photovoltaic and thermal energy systems may operate simultaneously to jointly meet the cooling load demand. For example, photovoltaic power drives the compressor, while thermal energy drives the dehumidification process, or the two parts of cooling capacity are superimposed. When solar resources are insufficient, the system can give priority to using modules with higher efficiency or more current resources. For example, if photovoltaic power generation is not enough to drive the compressor, thermal energy-driven absorption cooling may be used as the main cooling method, or the system can switch to the grid for supplementary power supply.

Advantages: Improved energy utilization efficiency, better ability to cope with changes in cooling load when solar resources fluctuate; can handle sensible heat and latent heat loads at the same time (especially combined with dehumidification).

Solar energy combined with conventional energy (mains electricity/gas) (Solar-Assisted Conventional System)

This mode is the most common hybrid form, with solar energy as the main energy source and conventional energy as auxiliary or backup.

Working principle:

Solar priority: Solar energy (whether photovoltaic power or solar thermal energy) is first used to drive the air conditioning system. For example, photovoltaic power drives the air conditioner, or solar thermal energy drives the absorption/adsorption chiller.

Traditional Energy Supplementation: When solar energy is insufficient to meet all cooling load requirements (such as on cloudy days, at night, or during peak loads), the system automatically switches or introduces utility power (to drive compression air conditioners) or gas (to provide supplementary heat sources for absorption/adsorption chillers) to make up for the energy gap.

Intelligent Control: A sophisticated control system is key, which monitors solar energy availability, indoor temperature, and cooling load, and intelligently dispatches the use of different energy sources to minimize traditional energy consumption while ensuring comfort.

Advantages: Greatly improves system reliability and operational stability, avoids intermittent cooling problems that pure solar energy systems may face; reduces the need for energy storage equipment, thereby reducing system cost and complexity.

Multi-Cooling Technology Combination

This type of hybrid system combines different types of cooling technologies (such as evaporative cooling, dehumidification cooling, mechanical compression, absorption/adsorption) with solar energy.

Working Principle:

For example, a system may use solar thermal energy to drive a dehumidification wheel to handle moisture in the air (latent heat load), and then use an evaporative cooler or a small mechanical compressor driven by solar photovoltaic power to handle the sensible heat load.

Another example might be absorption cooling as the primary cooling source, but when the ambient temperature is high and the absorption efficiency decreases, a supplementary mechanical compressor driven by photovoltaics provides additional cooling.

Advantages: Can be optimized for different climate conditions and cooling load characteristics to achieve more precise and efficient temperature and humidity control.

|

|

Core components of solar air conditioning

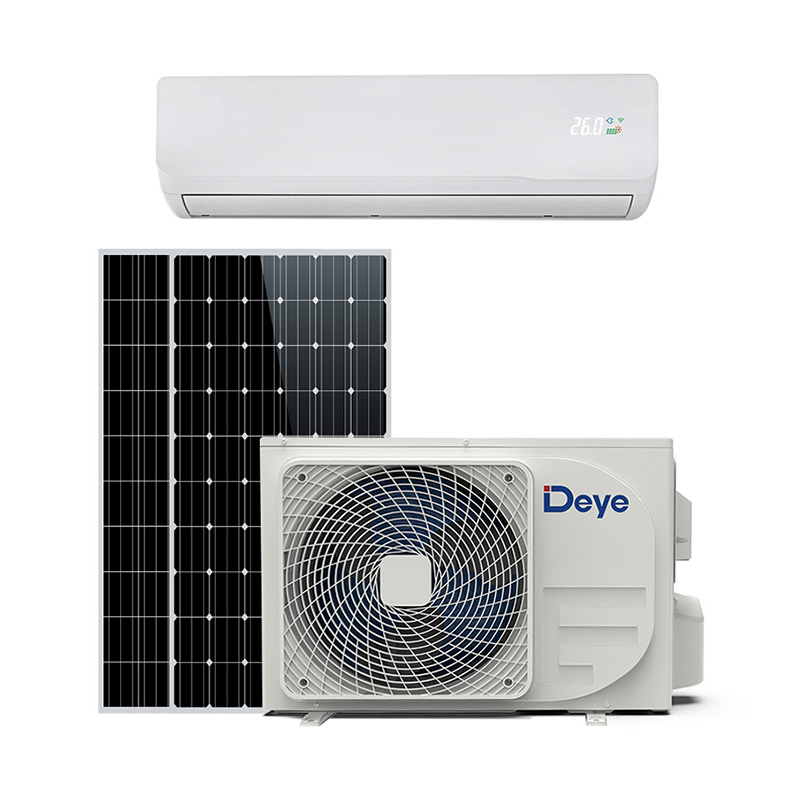

1. Solar Collectors or PV Panels

This is the "energy heart" of the solar air conditioning system, responsible for capturing solar energy.

Solar Thermal Collectors: Used in solar thermal driven air conditioning systems. They convert solar radiation into thermal energy. Common types include:

Flat-plate Collectors: Simple structure, relatively low cost, suitable for providing medium and low temperature hot water.

Evacuated Tube Collectors: Superior thermal insulation performance, higher energy efficiency, especially in winter or when the light is not strong, can provide medium and high temperature hot water.

Parabolic Trough Collectors: They generate higher temperature heat by focusing the sun's rays, and are often used in large commercial or industrial applications.

Photovoltaic (PV) Panels: They are used in solar photovoltaic-driven air conditioning systems. They convert sunlight directly into electricity. Common types include:

Monocrystalline PV Panels: They have high conversion efficiency and stable performance.

Polycrystalline PV Panels: They are relatively low cost and are the mainstream product in the market.

Thin-film PV Panels: They are flexible and have excellent performance in weak light power generation, but the conversion efficiency is usually low.

2. Refrigeration Cycle Core Equipment

This part is responsible for the actual refrigeration process.

Absorber/Generator - for Absorption Systems: In absorption refrigeration, the generator evaporates the refrigerant (usually water) from the absorbent (such as lithium bromide solution) by heating; the absorber reabsorbs the evaporated refrigerant.

Evaporator: It is crucial in all refrigeration systems. It is located in the space or fluid path that needs to be cooled, where the refrigerant evaporates and absorbs heat from the surrounding environment, thereby achieving cooling.

Condenser: In contrast to the evaporator, the refrigerant releases heat here and condenses into a liquid, usually dissipating the heat to the outdoor air or cooling water.

Compressor (Compressor - for PV-driven Systems): In photovoltaic-driven mechanical compression air conditioners, the compressor is the core component, responsible for compressing the refrigerant vapor, increasing its pressure and temperature, and is the power source of the entire refrigeration cycle.

3. Thermal/Cold Storage Unit

Not included in all systems, but it is essential to improve system efficiency and stability.

Hot Water Tank/Thermal Storage Tank: In solar thermal drive systems, it is used to store hot water generated by solar collectors so that cooling can be continuously provided at night or on cloudy days.

Ice Storage/Chilled Water Storage System: It can store the cooling energy generated at night or when solar energy is sufficient, and release it during peak hours or when solar energy is insufficient to balance supply and demand.

4. Control System and Auxiliary Equipment

Ensure efficient and safe operation of the system.

Controller: Monitors system parameters (such as temperature, light intensity), and automatically adjusts the operation of each component according to preset programs or user needs to optimize cooling effect and energy utilization.

Pumps/Fans: Responsible for conveying fluids (such as hot water, refrigerant, air) to ensure the effective transfer and distribution of heat or cold within the system.

Piping/Ducting System: Used to convey refrigerants, water or air and connect various components of the system.

Valves and Sensors: Control fluid direction and flow, monitor system operation status, and provide data to the controller.

Inverter - for PV-driven Systems: In a PV-driven system, if the air conditioner uses AC power, the inverter converts the DC power generated by the photovoltaic panel into AC power.

How does a hybrid solar air conditioner achieve heat-driven cooling?

The core of the hybrid solar air conditioning system to achieve heat-driven cooling is that it integrates absorption refrigeration or adsorption refrigeration technology, and through intelligent control strategies, it efficiently converts solar thermal energy into cooling capacity.

1. Solar heat collection and conversion

The first step in heat-driven cooling is to efficiently capture solar energy and convert it into usable thermal energy.

Solar collector: The system is usually equipped with solar collectors (such as vacuum tube collectors or flat plate collectors). These collectors absorb solar radiation and heat the fluid inside the collector (usually water or thermal fluid) to the required temperature. This hot water or hot fluid is the energy source for driving the refrigeration cycle.

Thermal storage unit: In order to cope with the intermittent nature of solar energy (such as at night or on cloudy days), the system usually includes a thermal storage tank. Excess heat generated during the day can be stored in it to ensure continuous cooling even when there is no sunlight, improving the system's operational stability and independence.

2. Heat-driven refrigeration cycle: absorption or adsorption

The heat energy obtained is introduced into the heat-driven refrigerator, which is the key link to achieve cooling.

Absorption refrigeration (Absorption Chilling):

Core principle: Absorption refrigeration uses the working fluid (such as water) to absorb heat at low temperature and low pressure, as well as the absorption and desorption characteristics of the absorbent (such as lithium bromide solution) to complete the refrigeration cycle.

Heat drive: The hot water or hot liquid provided by the solar collector is sent to the generator. In the generator, the heat heats the absorbent solution rich in the working fluid, causing the working fluid to evaporate from the solution.

Refrigeration process: The evaporated working fluid vapor enters the condenser to release heat and condense into liquid, and then enters the evaporator through the throttle valve. In the evaporator, due to the reduction in pressure, the liquid working fluid evaporates rapidly and absorbs heat from the surrounding environment, thereby reducing the temperature of the cooling water or air flowing through the evaporator to achieve refrigeration.

Cyclic regeneration: The working fluid vapor that has absorbed heat is then returned to the absorber, reabsorbed by the dilute solution to form a concentrated solution, and then pumped back to the generator to complete the entire closed cycle.

Adsorption Chilling:

Core Principle: Adsorption refrigeration uses the physical adsorption and desorption properties of solid adsorbents (such as silica gel, zeolite) on adsorbates (such as water, methanol).

Heat Driven: Solar heat is used to heat the adsorption bed filled with adsorbent. The heat causes the adsorbent to release (desorb) the adsorbate vapor pre-adsorbed on its surface.

Refrigeration Process: The desorbed adsorbate vapor is condensed into liquid in the condenser and then enters the evaporator. In the evaporator, the liquid adsorbent evaporates and absorbs heat, producing a cooling effect.

Cyclic regeneration: The evaporated adsorbate vapor is re-adsorbed by another cooled adsorption bed, and the adsorption bed cools and restores its adsorption capacity. Two or more adsorption beds take turns to perform heating desorption and cooling adsorption to achieve continuous refrigeration.

3. Hybrid and auxiliary modes

Hybrid systems are not just simply using solar thermal drive, but also have intelligent operating modes:

Solar priority: When there is sufficient sunshine, the system prioritizes using solar heat to drive the chiller to maximize energy saving benefits.

Auxiliary heat source: When solar energy is not enough to meet the cooling load demand, the system can automatically switch or introduce auxiliary heat sources, such as gas boilers or electric heaters, to supplement the heat and ensure uninterrupted cooling.

Multi-mode integration: Some advanced hybrid systems may also integrate solar photovoltaic power generation, which can drive circulation pumps, fans or other auxiliary equipment, or directly drive small mechanical compressors for supplementary cooling when the heat drive is insufficient, forming a more flexible solution.

What factors affect the COP of solar air conditioning systems

1. Solar Resource Characteristics

The quality and stability of solar resources directly affect the COP of solar air conditioning systems, especially for heat-driven systems.

Solar Irradiance: The higher the solar radiation intensity, the more energy can be captured by solar collectors or photovoltaic panels. For thermally driven systems, higher irradiance means hotter water or hot air, which usually improves the efficiency of absorption or adsorption chillers. For photovoltaic driven systems, higher irradiance directly generates more electricity, which drives the air conditioning system to operate more efficiently.

Sunshine Duration and Continuity: Continuous and stable sunshine allows the system to operate at its best for a long time. Intermittent sunshine causes the system to start/stop frequently or switch to auxiliary energy, which reduces the average COP.

Collector/PV Panel Tilt Angle and Orientation: The optimal tilt and orientation can maximize the capture of solar energy, thereby increasing the energy input of the system in different seasons and throughout the day, which in turn affects the COP.

2. Ambient Operating Temperatures

Ambient temperature is an important external factor that affects the COP of all refrigeration systems.

Condenser Temperature/Heat Sink Temperature: The refrigerant needs to release heat to the outside environment in the condenser. The higher the outside temperature, the higher the condensing temperature required for the condenser, which will increase the power consumption of the compressor (for photovoltaic drive systems) or reduce the efficiency of the heat-driven chiller, resulting in a decrease in COP. For absorption/adsorption systems, this means that the higher the cooling water or ambient air temperature, the worse the performance of the absorber/condenser, thereby reducing the COP.

Evaporator Temperature/Cooling Target Temperature: The evaporator is responsible for absorbing heat from the cooled space. The higher the temperature of the cooled space (i.e. the higher the evaporation temperature), the less work the refrigeration cycle needs to do, and the COP will generally be higher. Conversely, if the space needs to be cooled to a very low temperature, the COP will be reduced.

Generator Temperature - for Thermal Systems: For absorption or adsorption chillers, the higher the temperature of the driving heat source required for the generator (or desorption bed), the higher the COP can usually be achieved, but this also places higher requirements on the solar collector.

3. System Design and Component Performance

The internal design of the solar air conditioning system and the efficiency of each component are crucial to the COP.

Chiller Type and Efficiency:

Absorption/adsorption chillers: Different models and stages (single-effect, double-effect, triple-effect) of absorption chillers have different COPs. Double-effect and triple-effect units usually have higher COPs, but also have higher requirements for heat source temperature. Adsorption chillers usually have lower requirements for heat source temperature, but the COP may also be relatively low.

Compressor Efficiency - for PV-driven Systems: In photovoltaic-driven mechanical compression air conditioners, the efficiency of the compressor directly determines the efficiency of converting electrical energy into cooling capacity. Variable frequency compressors usually show higher COPs at partial loads.

Heat Exchanger Performance: The design and heat transfer efficiency of all heat exchangers (evaporators, condensers, generators, absorbers, etc.) in the system will affect the temperature difference between various parts of the system, and thus affect the COP. Good heat transfer performance helps to reduce the temperature difference and improve efficiency.

Piping and Ducting System Design: The length, diameter, insulation performance and layout of the pipes and ducts will affect the heat loss and pressure drop during fluid transportation, thereby affecting the energy consumption of pumps and fans, and indirectly affecting the total COP of the system.

Energy Storage System: A properly configured hot/cold energy storage system can smooth the volatility of solar energy, allowing the chiller to operate under more stable conditions, avoiding frequent start-up and shutdown, and thus maintaining a higher average COP.

4. Control Strategy and Operation Management

Intelligent control systems and reasonable operation management can optimize system performance.

Load Matching: Whether the system can flexibly adjust the use of solar energy and the output of cooling capacity according to the changes in real-time cooling load is crucial to maintaining a high COP.

Energy Management: In a hybrid system, how to intelligently switch between solar energy and auxiliary energy (such as city electricity and gas), and how to optimize the order of utilization of each energy source, will affect the overall COP of the system.

Maintenance and Cleaning: Regularly cleaning the surface of solar collectors or photovoltaic panels, keeping all components of the system in good operating condition, and preventing scaling, blockage and other problems are necessary to maintain a high COP.

How to design appropriate solar air conditioning capacity according to regional sunshine conditions

Designing solar air conditioning capacity is a complex project that requires comprehensive consideration of multiple factors related to regional sunshine conditions to ensure that the system can meet cooling needs and maximize the utilization efficiency of solar energy.

1. Assess Regional Solar Resources

This is the basis of design. Detailed and reliable local solar resource data is required.

Solar irradiance data: Obtain local annual average solar irradiance, monthly average irradiance, and peak irradiance data in different seasons. These data are usually expressed in kilowatt-hours per square meter per year (kWh/m²/year) or per day (kWh/m²/day), and need to distinguish between total radiation, direct radiation, and diffuse radiation.

Sunshine hours: Understand the local effective sunshine hours, especially in seasons with high cooling demand.

Meteorological data: Including ambient temperature, humidity, wind speed, etc., these data will affect the efficiency and cooling load of solar collectors.

Data source: You can refer to the long-term historical data of the National Meteorological Administration, professional meteorological stations, and renewable energy data centers (such as NASA and NREL).

2. Determine Cooling Load Requirements

Before designing any air conditioning system, it is crucial to accurately calculate the cooling load of the building.

Building characteristics: Consider the building's orientation, window area and type, wall and roof insulation, indoor heat sources (human body, electrical appliances), etc.

Usage: The purpose of the building determines its internal occupancy density, equipment heat generation and operating hours.

Design conditions: Set the indoor target temperature and humidity, as well as the outdoor design temperature (usually the typical temperature of the hottest day in the area).

Load calculation tool: Use professional building energy consumption simulation software (such as DOE-2, EnergyPlus, TRNSYS) or load calculation methods (such as sensible heat and latent heat separation method) to accurately calculate the required cooling capacity per hour or day (unit: kW or refrigeration tons).

3. Select Appropriate Solar Collector Type and Area

Select the most suitable collector type according to the required heat source temperature and local sunshine conditions.

Collector efficiency: Different collectors have different efficiency curves at different temperatures and irradiances. For example, vacuum tube collectors are more efficient at low temperatures and weak light conditions, and are suitable for absorption/adsorption chillers that require higher driving temperatures. Flat plate collectors are low-cost and suitable for providing medium and low temperature heat sources.

Collector area calculation: Calculate the total area of the required collector based on the driving heat demand of the chiller and the average thermal efficiency of the selected collector.

Required collector area = (driving heat required for the chiller) / (average thermal efficiency of the collector × solar irradiance)

A certain safety factor and loss are usually considered.

Installation considerations: Ensure that there is enough roof or ground space for installing the required area of collector, and consider shading, tilt and orientation to maximize the capture of solar energy throughout the year.

4. Match Chiller Capacity

Select an absorption or adsorption chiller that matches the cooling load demand.

Chiller COP: Consider the COP (coefficient of performance) of the chiller, which represents the ratio of cooling capacity to the required heat input. Different types and brands of chillers have different COPs, which are affected by driving temperature, condensing temperature, etc.

Rated cooling capacity: Select a chiller with a rated cooling capacity that matches the building's peak load.

Heat drive demand: Based on the rated cooling capacity and COP of the chiller, the required driving heat input is inferred, which is a key parameter for calculating the collector area.

5. Consider Thermal Storage System

The thermal storage system is essential for smoothing the intermittent supply of solar energy.

Capacity calculation: The capacity of the thermal storage tank needs to be calculated based on the required cooling capacity at night or on cloudy days and the specific heat capacity of the thermal storage medium.

Design principle: The thermal storage system should be able to store enough heat to support the operation of the chiller during periods without sunlight, or to reduce dependence on auxiliary energy.

6. Integrate Auxiliary Energy and Smart Control

A pure solar system may not be able to meet the cooling needs under all conditions, so auxiliary energy and smart control are required.

Auxiliary energy: Depending on the regional sunshine conditions and system reliability requirements, it may be necessary to integrate gas boilers, electric heaters or mains electricity (for photovoltaic-driven compressors) as supplementary energy when solar energy is insufficient.

Control strategy: Design an intelligent control system to optimize the use of solar energy based on parameters such as real-time solar energy availability, cooling load changes, and heat storage status, and intelligently schedule the intervention of auxiliary energy to maximize COP and system reliability.

DC R410A

| Items | Unit | 9000BTU | 12000BTU | 18000BTU |

| Mode | / | DGWA1-DC48V-09K | DGWA1-DC48V-12K | DGWA1-DC48V-18K |

| Voltage | V | DC48V(46~58V) | DC48V(46~58V) | DC48V(46~58V |

| Cooling Capacity | W | 2640(1000-2950) | 3510(1000-3700) | 5010(1300-5700) |

| Cooling power input | W | 640(180-750) | 930(200-1080) | 1360(250-1660) |

| Heating Capacity | W | 2900(800-3300) | 3900(1000-4000) | 5150(1500~5250) |

| Heating power input | W | 680(160-864) | 1030(180-1020) | 1260(250~1410) |

| EER | W/W | 4.10 | 3.80 | 3.68 |

| Indoor unit Dimension (WxHxD) | mm | 840x205x295 | 840x205x295 | 1080x330x237 |

| Indoor unit Packing (WxHxD) | mm | 920x290x360 | 920x290x360 | 1140x300x382 |

| Outdoor unit Dimension (WxHxD) | mm | 802x564x323 | 802x564x323 | 802x564x323 |

| Outdoor unit Packing (WxHxD) | mm | 910x622x405 | 910x622x405 | 910x622x405 |

-1.jpg)